Professional Electronics

Price range: $21,500.00 through $25,000.00

Professional Electronics

Intensive 5-Day Circuit Analysis and Component Integration for Industry Applications

Course Overview

Professional Electronics provides comprehensive training in electronic circuit analysis, component identification, and hands-on troubleshooting for industrial, automotive, and control system applications.

Target Audience: Engineering technicians, maintenance professionals, system integrators, and technical personnel working with industrial control systems, automotive electronics, and embedded applications.

Description

5-Day Intensive Structure

Following EOD Electronics Curriculum Topics

Day 1: Technician Skills and Basic DC Electronics

Foundation Skills and DC Circuit Analysis (8 hours)

Morning Session (4 hours):

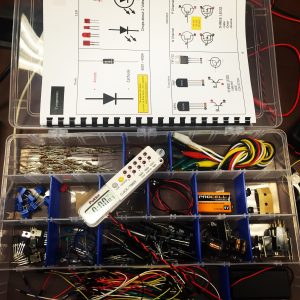

– Technician Skills: Digital multimeter operation (Fluke 101, 87V techniques)

– Breadboarding: Professional prototyping and circuit construction

– Through-hole soldering: Component mounting and connection techniques

– Basic DC: Voltage, current, resistance fundamentals

Afternoon Session (4 hours):

– Units of Measurement: Volt, amp, and ohm relationships

– Basic Circuits: Series circuits and parallel circuits analysis

– Kirchhoff’s Current Law: Current distribution in circuits

– Coulomb and Electric Charge: Fundamental electrical concepts

– Ohm’s Law: How voltage, current and resistance relate

– Ohm’s Law Triangle Technique: Practical calculation methods

– Analyzing Basic Circuits with Ohm’s Law: Real-world applications

Day 2: Resistors and Capacitors

Passive Component Analysis and Applications (8 hours)

Morning Session (4 hours):

– Resistors: Component fundamentals and applications

– Types of Resistors: Fixed and variable configurations

– Variable Resistors: Potentiometers and rheostats

– Thermistor: Temperature-sensitive resistance devices

– Photoresistor/LDR: Light-dependent resistors

– Varistor Resistor: Voltage-dependent resistors

– Surface Mount Resistor: SMD identification and handling

– Applications of a Resistor: Current limiting and voltage division

– Switches (COTS): Commercial off-the-shelf switching devices

Afternoon Session (4 hours):

– Capacitors: Energy storage fundamentals

– The Capacitance of a Capacitor: Basic principles

– Standard Units of Capacitance: Farad, microfarad, picofarad

– Capacitance of a Parallel Plate Capacitor: Design calculations

– The Dielectric of a Capacitor: Insulating materials

– Voltage Rating of a Capacitor: Maximum operating voltage

– Types of Capacitors: Material and construction varieties

Day 3: Diodes and Transistors

Active Semiconductor Components (8 hours)

Morning Session (4 hours):

– Diodes: Semiconductor fundamentals and applications

– Forward and reverse bias operation

– Rectification and voltage regulation circuits

– Protection circuits and signal processing

– Transistors: Amplification and switching applications

– BJT operation and biasing techniques

– MOSFET voltage-controlled switching

– Load line analysis and operating points

Afternoon Session (4 hours):

– Actuators: Electromechanical control devices

– History/Theory: Development of electromechanical devices

– Diagram – Electric Actuator: Motor and solenoid control

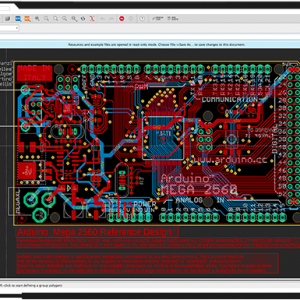

Day 4: Microcontrollers and Sensors with Arduino

Comprehensive Arduino Integration and Sensor Systems (8 hours)

Morning Session (4 hours):

– Arduino Fundamentals and Setup: Introduction to Arduino ecosystem

– Arduino Uno board architecture and pinout

– Digital I/O pins, analog inputs, PWM outputs

– Power supply options and voltage regulators

– Arduino IDE installation and configuration

– Building Arduino on Breadboard: ATmega328P microcontroller setup

– Crystal oscillator and timing circuits

– Reset circuit and programming interface

– Power supply decoupling and filtering

– Programming Essentials: Basic sketch structure

– Digital input/output operations

– Analog-to-digital conversion (ADC)

– Pulse Width Modulation (PWM) control

– Serial communication for debugging

Afternoon Session (4 hours):

– Digital Sensor Interfacing: Push buttons and mechanical switches

– PIR motion sensors

– Ultrasonic distance sensors (HC-SR04)

– Reed switches and Hall effect sensors

– Rotary encoders for position sensing

– Analog Sensor Integration: Temperature sensors (TMP36, thermistors)

– Light sensors (photoresistors, photodiodes)

– Potentiometers for user input

– Current and voltage sensing modules

– Signal conditioning and filtering

– Advanced Sensor Systems: I2C communication protocol and devices

– SPI communication for high-speed sensors

– ToF LIDAR distance measurement

– Accelerometers and gyroscopes

– Environmental sensors (humidity, pressure)

– Actuator Control: LED and LED strip control

– Relay modules for high-power switching

– Servo motor positioning

– DC motor control with H-bridges

– Stepper motor precision control

Day 5: Diagnostics and Troubleshooting with Fluke Meter

Professional Testing Procedures and Six-Step Troubleshooting Method (8 hours)

Morning Session (4 hours):

– Fluke Multimeter Mastery: Model comparison (Fluke 101 vs 87V)

– Safety ratings and CAT categories

– Proper probe selection and usage

– Min/Max recording and data logging

– True RMS vs average responding meters

– Advanced Measurement Techniques: Voltage measurements in live circuits

– Current measurement using clamp meters

– Resistance and continuity testing

– Capacitance and frequency measurements

– Diode and transistor testing modes

– Temperature measurements with thermocouples

– Specialized Testing Functions: Ghost voltage identification

– Burden voltage considerations

– Input impedance effects

– Relative mode measurements

– Peak hold and transient capture

Afternoon Session (4 hours):

– Six-Step Troubleshooting Method: Systematic approach to diagnostics

– Step 1 – Gather Information: Interview operators about symptoms

– Review equipment history and logs

– Document intermittent vs constant failures

– Step 2 – Understand the System: Review schematics and documentation

– Identify subsystems and signal flow

– Establish normal operating parameters

– Step 3 – Identify Possible Causes: List potential failure points

– Rank by probability

– Consider environmental factors

– Step 4 – Plan the Approach: Determine test sequence

– Select appropriate test equipment

– Identify safety considerations

– Step 5 – Test and Repair: Systematic voltage testing

– Current draw analysis

– Signal tracing techniques

– Component-level testing

– Safe component replacement

– Step 6 – Document and Follow Up: Record all measurements

– Update equipment logs

– Recommend preventive measures

– Practical Troubleshooting Exercises: Power supply diagnostics

– Sensor circuit fault finding

– Arduino system debugging

– Motor control troubleshooting

– Intermittent fault isolation

– Professional Best Practices: Safety-first approach

– Lockout/tagout procedures

– ESD protection methods

– Test equipment calibration

– Building a troubleshooting toolkit